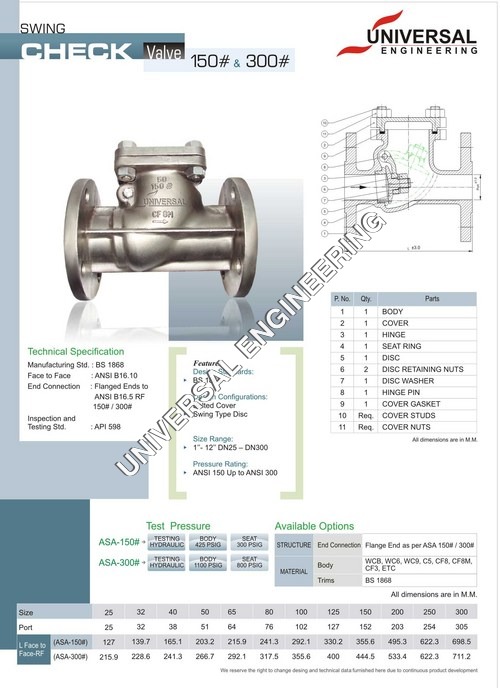

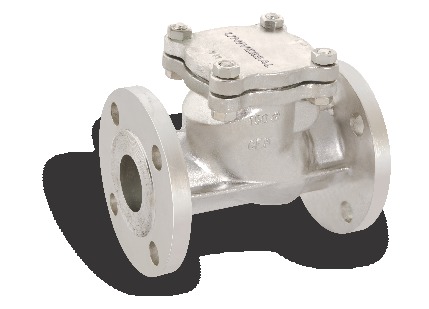

Swing Check Flanged Ends Valve

Swing Check Flanged Ends Valve Specification

- Application

- Industrial

- Structure

- Check

- Type

- Check Valve

- Media

- Water, Gas, Acid, Base, Oil

- Color

- Silver

Swing Check Flanged Ends Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- JNPT Nhava Sheva Port

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Packaging Details

- Box and Bag

- Main Domestic Market

- All India

About Swing Check Flanged Ends Valve

Specification

| Country of Origin | Made in India |

| Material | Stainless Steel |

| End Connection | Flange |

| Material Grade | SS304 SS316 |

| I Deal In | New Only |

| Brand | Universal |

| Valve Size | 15MM TO 200MM |

| Size | 25MM TO 200MM |

Engineered for Reliable Flow Control

Built with quality materials and a robust check valve structure, the Swing Check Flanged Ends Valve is suited for demanding industrial environments. Its flanged ends ensure secure attachment to pipelines handling diverse media, including corrosive acids and bases, as well as oil, water, and gas. Each valve meets strict manufacturing standards, ensuring long-term performance and safety.

Versatile Applications Across Industries

Whether it's water treatment, petrochemicals, or chemical processing, this valve efficiently prevents reverse flow, protecting sensitive equipment. Its corrosion-resistant silver finish and adaptability to a broad media spectrum make it a trusted choice for Indian industries and global markets alike.

FAQ's of Swing Check Flanged Ends Valve:

Q: How does the Swing Check Flanged Ends Valve work in industrial systems?

A: The valve allows fluid to flow freely in one direction but automatically closes to prevent backflow when the flow reverses. This protects pumps, compressors, and pipelines from damage due to reverse flow.Q: What are the main benefits of using this check valve for water, gas, acid, base, or oil applications?

A: This check valve provides reliable backflow prevention, resists corrosion from aggressive media, and maintains operational safety and efficiency for a wide range of fluids.Q: When should a Swing Check Flanged Ends Valve be installed in a pipeline?

A: It should be installed whenever it is essential to prevent backflow, particularly after pumps or in critical sections of industrial piping that handle hazardous or valuable media.Q: Where can I source Swing Check Flanged Ends Valves in India?

A: These valves are available from distributors, exporters, manufacturers, suppliers, traders, and wholesalers throughout India, serving both domestic and international industrial clients.Q: What is the process for installing a Swing Check Flanged Ends Valve?

A: The process involves aligning the flanged ends with the corresponding pipe flanges, securing them with bolts and gaskets, and ensuring proper orientation so that flow direction matches the valve's design.Q: Can this valve handle corrosive acids and bases as well as oil and gas?

A: Yes, the valve is constructed from materials designed to resist corrosion, making it suitable for use with a variety of aggressive and non-aggressive media.Q: What are the common industrial uses for this valve in India?

A: Typical uses include water supply systems, chemical processing plants, oil and gas refineries, and any application where safeguarding equipment from reverse flow is critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check And Non Return Valve Category

Casting Check Valves

Minimum Order Quantity : 1 , , Piece

Type : Check Valves

Structure : Check

Color : Silver

Pressure : High Pressure

S.S Vertical Screwed Ends Check Valve

Price 500 to 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Check Valve

Structure : Check

Color : Silver

Pressure : High Pressure

I.C 304/316 Disc Check Valve

Price 500.00 to 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Check Valve

Structure : Check

Color : Silver

Pressure : High Pressure

I.C 304 And 316 Wafer Flap Type Nrv Check Valve

Price 500.00 to 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Check Valve

Structure : Check

Color : Silver

Pressure : High Pressure

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry