Casting Check Valves

Casting Check Valves Specification

- Features

- Long Life, Durable

- Material

- Stainless Steel, Carbon Steel, and Bronze.

- Application

- Industrial

- Usage

- Water, Air, Gas

- Structure

- Check

- Voltage

- Coil - 230VAC 24VDC 12VDC 110VAC 240VAC24VAC Volt (v)

- Type

- Check Valves

- Size

- 25-900 mm

- Pressure

- High Pressure

- Media

- Water

- Port Size

- upto 12 inch

- Color

- Silver

- Temperature

- 180 DegreeF. Fahrenheit (oF)

Casting Check Valves Trade Information

- Minimum Order Quantity

- 1 , , Piece

- FOB Port

- JNPT Nhava Sheva Port

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Box and Bag

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa, Western Europe, Asia

- Main Domestic Market

- All India

About Casting Check Valves

We are recognized as an affluent entity, instrumental in offering a wide assortment of Casting Check Valves to our clients. With the aid of advanced tools and ultra-modern equipment, our team of highly skilled professionals manufactures these valves using premium grade raw material and sophisticated machinery. The offered valves are widely demanded in oil, chemical, beverage and pharmaceutical industries. We are providing these Casting Check Valves in various specifications and customized options according to the needs of our clients

Features:

-

Application specific design

-

Strong construction

-

Corrosion resistance

-

User friendly

Specifications:

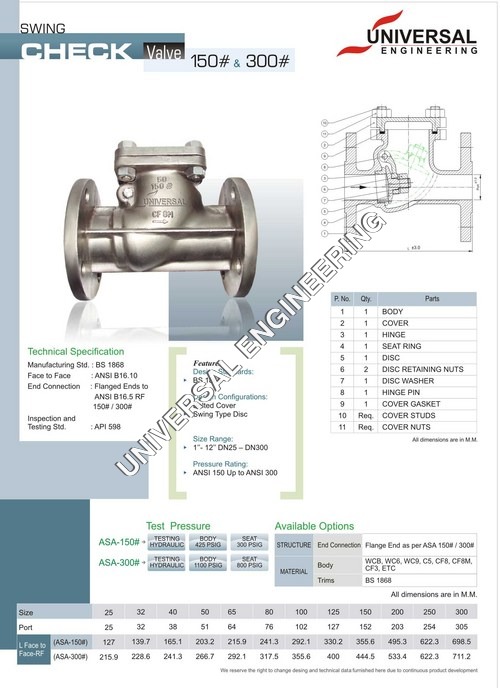

The cast steel swing check ( Reflux)valves are also available in class 150, 300 & 600 in flanged end.

Engineered for Industrial Water Systems

These check valves are specifically designed for industrial water handling, featuring high-pressure capability and superior resistance to corrosion. Trusted by engineers, our valves maintain efficient flow control and adaptive performance even in demanding conditions. Their casting structure guarantees robustness and long service life, making them indispensable in pipelines and process plants.

Flexible Sizing and Reliable Operation

Offered in a broad range of sizes from 25 mm up to 900 mm, these casting check valves cater to diverse industrial applications. The check mechanism prevents reverse flow, protecting equipment and maintaining operational safety. Their silver-finished construction enhances both durability and visual appeal for rigorous industrial environments.

FAQ's of Casting Check Valves:

Q: How do casting check valves function in high-pressure water systems?

A: Casting check valves operate using a check mechanism that allows water to flow only in one direction. When water tries to reverse its flow, the valve automatically closes, thus preventing backflow and protecting equipment from potential damage in high-pressure industrial water systems.Q: What are the key benefits of using casting check valves for industrial applications?

A: Casting check valves provide robust performance in high-pressure environments, prevent water backflow, protect system integrity, and require minimal maintenance. Their durable construction ensures longevity and reliability in continuous industrial use.Q: Where can casting check valves of sizes 25 mm to 900 mm be installed?

A: These check valves are suitable for installation in a variety of industrial settings such as water treatment plants, power generation facilities, chemical industries, and large-scale pipelines wherever reliable backflow prevention is critical.Q: When should casting check valves be selected over other valve types?

A: Choose casting check valves when your system requires automatic prevention of reverse water flow, especially under high-pressure conditions. They are ideal where minimal operator intervention and robust, leak-resistant operation are necessary.Q: What is the typical process for ordering and receiving casting check valves from your company?

A: As a manufacturer, distributor, exporter, supplier, trader, and wholesaler in India, we streamline your procurement process. You can consult our technical team with your specifications, receive detailed quotations, and get reliable delivery timelines to match your project schedule.Q: How are casting check valves used in industrial water handling systems?

A: They are installed within pipelines to ensure water moves in the intended direction. Their automatic closure on flow reversal makes them vital for maintaining safety and efficiency in water distribution, wastewater management, and process systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Check And Non Return Valve Category

I.C 304/316 Dual Plate Check Valve

Price 500.00 to 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Type : Check Valve

Media : Water, Gas, Other, Acid, Base, Oil

Structure : Check

I.C 304/316 Horizontal Screwed Ends Check Valve

Price 500 to 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Type : Check Valve

Media : Water, Oil, Acid, Gas, Other, Base

Structure : Check

S.S Vertical Screwed Ends Check Valve

Price 500 to 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Type : Check Valve

Media : Water, Gas, Other, Acid, Base, Oil

Structure : Check

Cast Steel Swing Flanged Ends Check Valve

Price 5000 to 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Type : Check Valve

Media : Water, Gas, Other, Acid, Base, Oil

Structure : Check

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry