Call: 08045802361

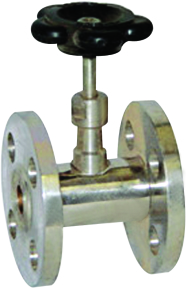

Screwed Ends Needle Valve

Price 300 INR/ Piece

MOQ : 100 Pieces

Screwed Ends Needle Valve Specification

- Connection Type

- Flanged

- Material

- Stainless Steel, SS304 SS316

- Application

- Industrial

- Structure

- Needle

- Usage

- Air, Gas, Water

- Type

- Needle Valve

- Size

- 25MM TO 200MM

- Pressure

- High Pressure

- Media

- Water

- Port Size

- 15 mm (1/2 inch)

- Color

- Silver

- Temperature

- 180 Fahrenheit (oF)

Screwed Ends Needle Valve Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- JNPT Nhava Sheva Port

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Packaging Details

- Box and Bag

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Screwed Ends Needle Valve

Specification

|

Country of Origin |

Made in India |

|

Material |

Stainless Steel |

|

Structure Type |

Needle |

|

Material Grade |

SS202 SS304 SS316 |

|

End Connection Type |

Screw End |

|

Brand |

UNIVERSAL |

|

Size |

08MM TO 50MM |

Precision Control for Industrial Needs

The Screwed Ends Needle Valve offers superior flow regulation, making it an essential component in industrial settings handling water under high pressure. Its needle structure ensures minimal leakage and steady operation, providing peace of mind in demanding environments.

Trusted by Leading Indian Suppliers

Designed and manufactured by experienced distributors, exporters, and suppliers in India, this needle valve meets stringent quality standards. Whether you are a wholesaler or a trader, you can rely on its long-lasting performance and reliable supply chain support.

FAQ's of Screwed Ends Needle Valve:

Q: How is the Screwed Ends Needle Valve installed in industrial water systems?

A: The valve is equipped with screwed ends, allowing for easy installation using standard piping tools. Simply tighten the valve onto the threaded ends of your system pipes to ensure a secure and leak-proof connection.Q: What benefits does this needle valve provide for high-pressure water applications?

A: This valve delivers precise flow control, minimizes leakage, and withstands high pressure, making it highly reliable for challenging industrial environments. Its robust construction ensures long-term efficiency and reduced maintenance.Q: When should I choose a needle valve with a screwed end design?

A: You should opt for a screwed ends needle valve when you require an effective and secure valve solution for systems that need frequent maintenance, easy installation, or regular part replacement without welding.Q: Where is this needle valve commonly used within industry?

A: This type of needle valve is typically used in water distribution systems, process pipelines, laboratory settings, and chemical processing plants where precise control of water flow under high pressure is necessary.Q: What is the manufacturing process for these needle valves?

A: The manufacturing process involves selecting premium materials, precision machining the needle structure, ensuring exact threading for the screwed ends, and applying a durable silver finish for enhanced corrosion resistance.Q: How should this needle valve be maintained for optimal performance?

A: Regular inspection for signs of wear, periodic tightening of the screw connections, and cleaning of internal components are recommended maintenance practices to keep the valve functioning efficiently in industrial settings.Q: What usage advantages does this needle valve offer to suppliers and wholesalers in India?

A: Suppliers and wholesalers benefit from the valve's robust build, consistent demand in water-intensive industries, and compliance with industry standards. Its reliability reduces returns and strengthens supplier reputation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Needle Valve Category

S.S 316 Flanged Ends Needle Valve

Price 300 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Media : Water

Material : Stainless Steel, Carbon Steel, and Bronze.

Structure : Needle

High Pressure Screwed Ends Needle Valve

Minimum Order Quantity : 100 Pieces

Color : Silver

Media : Water

Material : Stainless Steel, SS304 SS316

Structure : Needle

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry