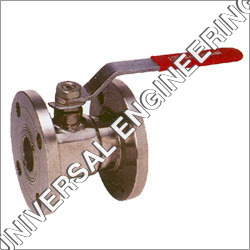

Industrial Valves

Industrial Valves Specification

- Material

- Stainless Steel, Carbon Steel, and Bronze.

- Features

- Long Life, Durable

- Usage

- Water, Air, Gas

- Structure

- Safety

- Application

- Industrial

- Voltage

- Coil - 230VAC 24VDC 12VDC 110VAC 240VAC24VAC Volt (v)

- Type

- Valve

- Size

- 15-1000 mm

- Pressure

- High Pressure

- Media

- Water

- Port Size

- upto 12 inch

- Color

- Silver

- Temperature

- 180 DegreeF. Fahrenheit (oF)

Industrial Valves Trade Information

- Minimum Order Quantity

- 1 , , Piece

- FOB Port

- JNPT Nhava Sheva Port

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 200 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Box and Bag

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, South America, Asia, Central America

- Main Domestic Market

- All India

About Industrial Valves

With rich industry experience and the help of our competent workforce, we are offering our clients a broad array of Industrial Valves. Manufactured using the best quality raw materials, these precisely manufactured valves are highly appreciated all over the world due to their features like durable finish standards and high strength. These valves are used in chemical, beverage, oil, pharmaceutical and other allied industries for controlling flow of oil, gas and liquid. We offer these Industrial Valves to our clients at industry leading rates.

Features:

-

Durable finish

-

Corrosion resistance

-

High strength

-

Excellent durability

Reliable Water Control Solutions

Our valves provide consistent and secure water regulation in high-pressure industrial environments. Crafted with safety structures and a corrosion-resistant silver finish, these valves withstand demanding operational conditions. With seamless adaptability to various installation scales, they ensure optimal control over water systems, helping industries maintain productivity and safety.

Comprehensive Supply Network

As a multifaceted supplier, manufacturer, trader, and wholesaler in India, we offer a diverse range of industrial water valves. Whether for local installation or global export, our extensive distribution channels guarantee timely and efficient delivery. Our expertise ensures that clients receive valves tailored precisely to their industrial specifications.

FAQ's of Industrial Valves:

Q: How are industrial valves used in high-pressure water applications?

A: Industrial valves with a safety structure are installed in water pipelines to regulate or isolate flow, especially where high pressure is involved. They ensure safe operation, preventing water leaks and protecting equipment and personnel.Q: What sizes are available for these high-pressure safety valves?

A: Our valves come in a broad range of sizes, from 15 mm for smaller piping systems up to 1000 mm for large-scale industrial applications, accommodating diverse operational needs.Q: When should high-pressure safety valves be replaced or maintained?

A: Regular maintenance is essential for optimal performance. It's advisable to inspect and service valves every six to twelve months, and to replace them if leakage, corrosion, or performance drops are detected.Q: Where can these industrial water valves be sourced in India?

A: These valves are available through our distribution network across India. Being manufacturers, suppliers, traders, and wholesalers, we cater to both domestic and international orders.Q: What is the process for exporting industrial valves from India?

A: We handle the complete export process: from product customization to meet international standards, packaging, documentation, and shipment, ensuring our valves reach global clients securely and efficiently.Q: How do safety-structured valves benefit industrial water systems?

A: Safety-structured valves improve operational safety by minimizing risk of accidental leaks or bursts in high-pressure environments, enhancing equipment longevity and system reliability.Q: What media are compatible with these valves?

A: These industrial valves are optimized for water media and can sustain consistent performance in high-pressure water systems commonly used in many industrial sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gate Valve Category

SS Single Piece Flanged End

Minimum Order Quantity : 50 Pieces

Material : Stainless Steel, Carbon Steel, and Bronze.

Pressure : High Pressure

Color : Silver and Grey

Usage : Water, Air, Gas

S.S. Gauge Glass Cock Flanged End

Price 2400 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel, SS304 SS316

Pressure : High Pressure

Color : Silver

Usage : Air, Gas, Water

SS Three Piece Flanged End

Minimum Order Quantity : 1 Piece

Material : Stainless Steel, Carbon Steel, and Bronze.

Pressure : High Pressure

Color : Silver

Usage : Water, Air, Gas

SS Heavy Type Screwed End

Minimum Order Quantity : 1 Piece

Material : Stainless Steel, Carbon Steel, and Bronze.

Pressure : High Pressure

Color : Grey and Silver

Usage : Water, Air, Gas

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry