I.c 304 316 Y Type Strainer Flanged Ends

Price 3476 INR/ Piece

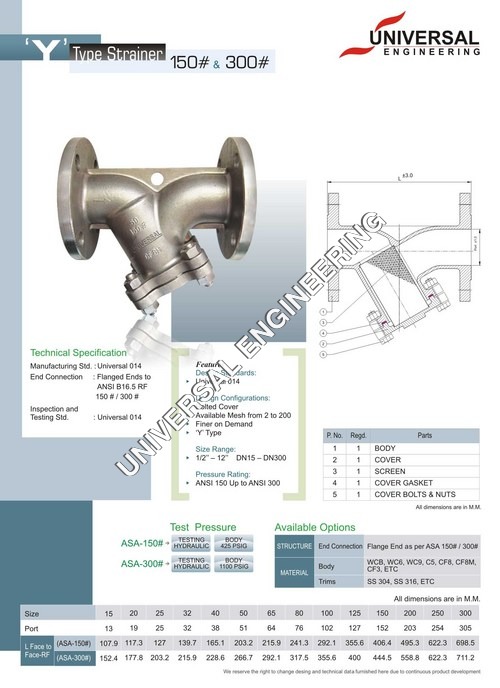

I.c 304 316 Y Type Strainer Flanged Ends Specification

- Application

- Industrial

- Type

- STRAINER

- Power

- Ball Screw

- Pressure

- High Pressure

- Media

- Oil, Gas, Water, Acid, Base

- Color

- Silver

I.c 304 316 Y Type Strainer Flanged Ends Trade Information

- Minimum Order Quantity

- 1 , , Piece

- FOB Port

- JNPT Nhava Sheva Port

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 1 Days

- Packaging Details

- Box and Bag

- Main Domestic Market

- All India

About I.c 304 316 Y Type Strainer Flanged Ends

- MOC : CF 8 (304) / CF8M (316)

- Size : 15 mm to 150 mm

Specification

|

Valve Type |

Y |

|

Country of Origin |

Made in India |

|

Brand |

UNIVERSAL |

|

Size/Dimension |

25MM TO 150MM |

|

Material |

INVESTMENT CASTING |

|

Design Type |

Y TYPE |

|

I Deal In |

New Only |

|

End Connection |

Flange End |

|

Media |

Oil |

|

Bolts & Nuts |

BOLTED COVER |

Reliable Filtration for Multiple Media

Built to excel in rigorous industrial environments, the I.C 304/316 Y Type Strainer efficiently filters oil, gas, water, acids, and bases. The high-quality stainless steel construction ensures long-lasting corrosion resistance, making it suitable for a variety of challenging applications. Its robust flanged end design allows for secure integration into high-pressure pipelines.

Precision Engineering and Enhanced Usability

Equipped with a power-driven ball screw, this Y type strainer is engineered for smooth operation and simple maintenance. The Y configuration impedes clogging and enables easy cleaning, thus reducing downtime and prolonging the equipment life of your industrial systems. Its compatibility with high-pressure usage highlights its reliability for critical process flows.

Serving a Wide Range of Industrial Needs

India's leading exporters, manufacturers, suppliers, traders, and wholesalers offer this Y type strainer for versatile installations. Whether for new projects or retrofitting, its universal design, robust build, and superior filtration make it an ideal choice for refineries, chemical plants, water treatment, and other high-pressure industrial sectors.

FAQ's of I.c 304 316 Y Type Strainer Flanged Ends:

Q: How does the I.C 304/316 Y Type Strainer operate in industrial pipelines?

A: This Y Type Strainer uses a stainless steel mesh to capture solid debris from process fluids such as oil, gas, water, acids, and bases. Its flanged ends allow secure installation in high-pressure pipelines, and the power-assisted ball screw ensures effortless strainer cover operation during maintenance.Q: What benefits does using a 304/316 stainless steel strainer provide?

A: Stainless steel 304/316 offers excellent resistance to corrosion and chemical reactions, making the strainer highly durable in harsh industrial environments. These materials help ensure the device maintains its integrity and functionality across a wide range of media and temperatures.Q: When is it necessary to clean or maintain the Y Type Strainer?

A: Maintenance should be performed based on system operating conditions and the level of impurities in your media. Regular inspection and cleaning are recommended to avoid clogging and maintain optimal flow, typically scheduled during routine plant downtime or as determined by pressure differential indicators.Q: Where are I.C 304/316 Y Type Strainers mainly installed?

A: They are widely used in industrial settings across India, including oil and gas facilities, chemical plants, water treatment units, and acid/base handling systems. Wherever high-pressure filtration of liquids or gases is required, these Y strainers offer reliable protection for sensitive downstream equipment.Q: What is the process for installing the strainer in a high-pressure pipeline?

A: Installation involves aligning the flanged ends of the strainer with the mating flanges on your pipeline. After ensuring proper gasket placement, bolts are tightened to recommended torque specifications. The power ball screw mechanism assists with cover handling during installation and future maintenance.Q: How does the strainer improve operational efficiency and equipment longevity?

A: By effectively trapping particulates and debris before they reach critical machinery, the strainer minimizes wear, reduces downtime, and maintains consistent equipment performance. This preventive action helps lower maintenance costs and extends the operational lifespan of your industrial systems.Q: What distinguishes this Y Type Strainer from standard models?

A: The unique combination of power-operated ball screw actuation, corrosion-resistant 304/316 stainless steel body, flanged ends for secure fitting, and its adaptability for various aggressive and standard media sets it apart as a premium, high-efficiency filtration solution.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Strainer Flanged Category

'Y' Type Strainer

Minimum Order Quantity : 1 , , Piece

Media : Water

Pressure : High Pressure

Type : Strainer

Application : Industrial

Cast Iron Y Type Strainer Screwed Ends

Price 900.00 to 25000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Media : Base, Gas, Acid, Water, Oil, Other

Pressure : High Pressure

Type : STRAINER

Application : Industrial

I.C 304/316 Y Type Strainer Screwed Ends

Price 520 INR / Piece

Minimum Order Quantity : 1 , , Piece

Media : Water, Acid, Oil, Gas, Other, Base

Pressure : High Pressure

Type : STRAINER

Application : Industrial

Cast Iron T Type Strainer Flanged

Price 900.00 to 25000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Media : Base, Gas, Other, Oil, Water, Acid

Pressure : High Pressure

Type : STRAINER

Application : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry