Call: 08045802361

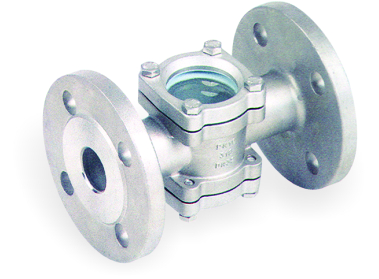

I.C 304/316 Sight Glass / View Glass

Price 2060 INR/ Piece

MOQ : 1 Piece

I.C 304/316 Sight Glass / View Glass Specification

- Application

- Industrial

- Type

- SIGHT GLASS VALVE

- Power

- Solenoid

- Pressure

- High Pressure

- Media

- Gas, Base, Oil, Acid, Water

- Color

- Silver

I.C 304/316 Sight Glass / View Glass Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- JNPT Nhava Sheva Port

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Box and Bag

- Main Export Market(s)

- Asia, Australia, Central America, North America, Eastern Europe, Middle East, Africa

- Main Domestic Market

- All India

About I.C 304/316 Sight Glass / View Glass

IC Sight Glass / View Glass

- MOC : CF8 (304) CF8M (316)

- Size : 25 mm to 150 mm

Specification

|

Country of Origin |

Made in India |

|

Material |

STAINLESS STEEL |

|

Size |

25MM TO 150MM |

|

Type |

Full View Sight Glass |

|

Usage/Application |

Power Plant |

|

Brand |

UNIVERSAL |

Precision Engineering for Demanding Applications

The I.C 304/316 sight glass is engineered to provide clear, instantaneous visual monitoring in critical industrial processes. Its stainless steel construction ensures excellent resistance to corrosion, making it suitable for media like acids, bases, oils, gases, and water under high-pressure conditions.

Reliable Operation for Enhanced Safety

Equipped with a solenoid-powered mechanism, this sight glass valve delivers reliable performance and precise control even in challenging operating environments. Its durable design enhances operational safety across a range of industrial sectors.

FAQ's of I.C 304/316 SIGHT GLASS / VIEW GLASS:

Q: How does the I.C 304/316 Sight Glass function in an industrial system?

A: The sight glass allows operators to visually monitor the flow and condition of media-such as gas, oil, water, acid, or base-within pipelines or tanks. Its solenoid valve facilitates automated control, ensuring high-pressure containment while offering real-time observation.Q: What types of media can the I.C 304/316 Sight Glass handle?

A: This sight glass is designed to support a wide spectrum of industrial media, including gases, oils, water, acids, and bases, making it a versatile monitoring component for various processes.Q: When should I use a sight glass valve in my process line?

A: A sight glass valve is essential whenever visual inspection of flow or clarity is required-such as checking for blockages, contamination, or proper liquid/gas distribution-especially in high-pressure and corrosive environments.Q: Where is the I.C 304/316 Sight Glass typically installed?

A: It is commonly installed in pipelines, reactors, and storage tanks across chemical, oil & gas, pharmaceutical, and water treatment plants. Its robust construction suits environments where durable, corrosion-resistant observation tools are critical.Q: What is the process for installing the sight glass valve?

A: Installation involves securing the sight glass valve between pipeline flanges or at a designated inspection point. It is important to ensure proper sealing and alignment, followed by connecting the solenoid control if automation is required.Q: How does using a stainless steel sight glass benefit industrial applications?

A: The use of SS 304/316 ensures long-lasting resistance to corrosion and chemical attack, providing reliable performance and safety in aggressive media and high-pressure situations.Q: What makes sourcing from Indian distributors and manufacturers advantageous?

A: India-based suppliers offer competitive pricing, a wide selection of specifications, and reliable after-sales support, making it easier for industrial clients to obtain and maintain quality sight glass valves tailored to their requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sight Glass Valve Category

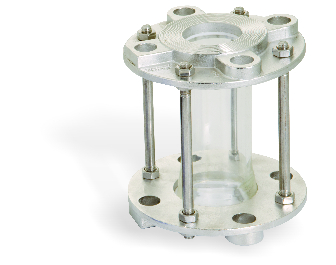

I.C 304/316 Double Window Sight Glass

Price Range 500.00 - 15000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Other, Oil, Gas, Acid, Water, Base

Color : Silver

Application : Industrial

Mild Steel Sight Glass Flanged Ends

Price 1313 INR / Piece

Minimum Order Quantity : 1 Piece

Media : Water, Gas, Base, Oil, Acid, Other

Color : Red

Application : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry