Cast Steel Screwed Ends Ball Valve

Price 725 INR/ Piece

Cast Steel Screwed Ends Ball Valve Specification

- Features

- Long Life, Durable

- Material

- Stainless Steel, Carbon Steel, and Bronze.

- Usage

- Water, Air, Gas

- Voltage

- Coil - 230VAC 24VDC 12VDC 110VAC 240VAC24VAC Volt (v)

- Application

- Industrial

- Structure

- Ball

- Type

- Ball Valve

- Power

- Ball Screw

- Size

- 15 mm (1/2 inch) - 8 Inch

- Pressure

- High Pressure

- Media

- Water

- Port Size

- upto 12 inch

- Color

- Red

- Temperature

- 180 DegreeF. Fahrenheit (oF)

Cast Steel Screwed Ends Ball Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- JNPT Nhava Sheva Port

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 1 Days

- Packaging Details

- Box and Bag

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Cast Steel Screwed Ends Ball Valve

- MOC : Carbon Steel (W.C.B.)

- Size : 15 mm to 100 mm

Specification

|

Country of Origin |

Made in India |

|

Material |

CAST STEEL - WCB |

|

Ends |

SCREWED |

|

Brand |

Universal |

|

Connector Type |

Screwed |

|

Valve Size |

15MM TO 50MM |

|

Size |

15MM TO 50MM |

Reliable High-Pressure Control

Our Cast Steel Screwed Ends Ball Valve is built to manage high-pressure industrial water systems with confidence. Its sturdy ball structure and secure screwed ends ensure dependable flow control, while the red finish allows for easy identification. This valve is ideal for applications where performance, safety, and longevity are paramount.

Versatile Industrial Application

Designed for a variety of industrial environments, this ball valve is perfect for manufacturers, suppliers, traders, and wholesalers who require reliable water flow management. Its construction supports high-pressure use, making it suitable for demanding operations across different sectors in India.

FAQ's of Cast Steel Screwed Ends Ball Valve:

Q: How is a Cast Steel Screwed Ends Ball Valve installed in industrial water systems?

A: Installation involves threading the screwed ends of the valve onto compatible pipe fittings. Proper sealing materials and tools should be used to ensure a leak-proof connection and optimal performance under high pressure.Q: What makes this ball valve suitable for high-pressure applications?

A: The cast steel construction provides strength and durability, while the precision-engineered ball mechanism ensures efficient control and tight sealing for high-pressure water flow scenarios.Q: When should I consider using a Cast Steel Ball Valve over other types of valves?

A: Choose this ball valve when you need reliable shutoff and control in high-pressure industrial water systems. Its ball design offers lower torque operation and quicker opening/closing compared to gate or globe valves.Q: Where can these ball valves be sourced in India?

A: You can obtain these ball valves through a network of distributors, exporters, manufacturers, suppliers, traders, and wholesalers throughout India who specialize in industrial valve solutions.Q: What is the process for maintaining a Cast Steel Screwed Ends Ball Valve?

A: Routine maintenance includes periodic inspection for leaks, cleaning of the ball and internal components, and checking for signs of wear or corrosion. Lubrication of moving parts may also be recommended.Q: How does the use of a ball screw mechanism benefit valve operation?

A: The ball screw mechanism minimizes friction, enabling smoother, more efficient movement of the valve, resulting in less wear and longer operational life.Q: What are the key benefits of using a Cast Steel Screwed Ends Ball Valve for water applications?

A: Key benefits include high-pressure compatibility, robust corrosion resistance, ease of installation, secure sealing, and long-term reliability in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Valve Category

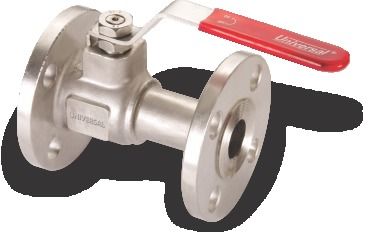

Flanged Ends Ball Valve

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Port Size : upto 12 inch

Type : Ball Valve

Material : Stainless Steel, Carbon Steel, and Bronze.

Structure : Ball

I.C 304/316 Flanged Ends Ball Valve

Price 1900 INR / Piece

Minimum Order Quantity : 1 Piece

Port Size : upto 12 inch

Type : Ball Valve

Material : Stainless Steel, Carbon Steel, and Bronze.

Structure : Ball

Cast Iron Flanged Ends Ball Valve

Price 828 INR / Piece

Minimum Order Quantity : 1 Piece

Port Size : upto 12 inch

Type : Ball Valve

Material : Stainless Steel, Carbon Steel, and Bronze.

Structure : Ball

Mild Steel Flanged Ends Ball Valve

Minimum Order Quantity : 1 Piece

Port Size : upto 12 inch

Type : Ball Valve

Material : Stainless Steel, Carbon Steel, and Bronze.

Structure : Ball

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry