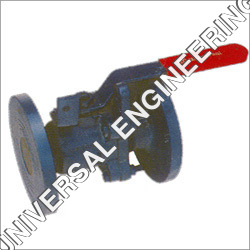

Cast Iron Flanged Ends Gate Valve

Price 3000 INR/ Piece

Cast Iron Flanged Ends Gate Valve Specification

- Features

- Long Life, Durable

- Material

- Stainless Steel, Carbon Steel, and Bronze.

- Usage

- Water, Air, Gas

- Structure

- Gate

- Voltage

- Coil - 230VAC 24VDC 12VDC 110VAC 240VAC24VAC Volt (v)

- Application

- Industrial

- Type

- Gate Valve

- Size

- 15 mm (1/2 inch) - 8 Inch

- Pressure

- High Pressure

- Media

- Water

- Port Size

- upto 12 inch

- Color

- Silver

- Temperature

- 180 DegreeF. Fahrenheit (oF)

Cast Iron Flanged Ends Gate Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- JNPT Nhava Sheva Port

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 1 Days

- Packaging Details

- Box and Bag

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

About Cast Iron Flanged Ends Gate Valve

CAST IRON GATE VALVE FLANGED ENDS

- MOC: C.I

- SIZE: 25mm TO 1000mm

- CLASS: 150# , 300# , 600#

Specification

|

Country of Origin |

Made in India |

|

Material |

CAST STEEL |

|

End Connection Type |

Flanged |

|

Size |

25MM TO 200MM |

Durable Gate Valve Solution

Our Cast Iron Flanged Ends Gate Valve stands out for its sturdy construction and efficient performance in demanding industrial environments. It is specially crafted to handle water with high-pressure flow, ensuring minimal leakage and resistance. The silver color adds corrosion resistance and aesthetic value, making it suitable for long-term use.

Versatile Applications Across Industries

Designed for industrial water systems, this valve's gate structure provides precise flow regulation. Its flanged ends enable easy integration into new or existing piping networks, ensuring versatility in both replacement and fresh installations. As a trusted supplier in India, we deliver reliable products that meet diverse operational requirements.

FAQ's of Cast Iron Flanged Ends Gate Valve:

Q: How is the Cast Iron Flanged Ends Gate Valve installed in an industrial water system?

A: The valve is installed by mounting its flanged ends onto compatible pipeline flanges using bolts and gaskets, ensuring a secure and leak-resistant connection suitable for handling high-pressure water.Q: What advantages does a gate-type structure offer for water application?

A: A gate-type structure provides precise shut-off and regulation, allowing full flow or complete closure, which is ideal for managing water distribution in high-pressure industrial systems.Q: When should industrial facilities consider using a high-pressure gate valve?

A: Industrial facilities should use this valve when their water systems require robust flow control, reliable sealing under high pressure, and durable materials that withstand frequent operation.Q: Where can this gate valve be sourced in India?

A: This valve is available throughout India via our network of distributors, suppliers, traders, wholesalers, and directly from us as the manufacturer and exporter.Q: What is the process for maintaining a cast iron gate valve in industrial settings?

A: Routine inspection, tightening of flanged connections, lubrication of moving parts, and cleaning to remove sediment buildup are essential processes for prolonging the valve's operational life and efficiency.Q: How does using this gate valve benefit industrial water systems?

A: Employing this gate valve enhances water system safety, ensures dependable pressure management, and reduces maintenance downtime due to its strong construction and efficient sealing capabilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gate Valve Category

C.I. Two Piece Flanged End

Price 1755 INR / Piece

Minimum Order Quantity : 1 Piece

Port Size : upto 12 inch

Pressure : High Pressure

Type : Ball Valve

Color : Grey and Black

SS Heavy Type Screwed End

Minimum Order Quantity : 1 Piece

Port Size : upto 12 inch

Pressure : High Pressure

Type : Ball Valve

Color : Grey and Silver

Cast Steel Flanged Ends Gate Valve

Price 229167 INR / Piece

Minimum Order Quantity : 10 Pieces

Port Size : upto 12 inch

Pressure : High Pressure

Type : Gate Valve

Color : Silver

S.S. Gauge Glass Cock Flanged End

Price 2400 INR / Piece

Minimum Order Quantity : 100 Pieces

Port Size : 15 mm (1/2 inch)

Pressure : High Pressure

Type : GUAGE GLASS COCK SET

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry